Advanced Alternative Fuel for Cement Production

Advanced Alternative Fuel for Cement Production

- 2024-12-31

- 8:0

- In person/online

Course description

Technical Competencies 1. Understand the landscape of alternative fuel systems in cement production. 2. Assess and select appropriate alternative fuels for specific kiln systems. 3. Optimize raw mix design considering alternative fuel integration. 4. Implement effective alternative fuel feeding and combustion strategies. 5. Monitor and control critical process parameters. 6. Understand the impacts of alternative fuels on clinker and cement quality. Quality and Compliance Objectives 7. Develop robust quality control protocols for alternative fuel utilization. 8. Ensure regulatory compliance and environmental performance. 9. Implement comprehensive safety and risk management strategies. Strategic and Economic Objectives 10. Conduct economic feasibility assessments of alternative fuel projects. 11. Drive continuous improvement in alternative fuel technologies. 12. Promote sustainable practices in cement production. Specific Egyptian Context Objectives 13. Evaluate the availability and feasibility of alternative fuels in Egypt. 14. Understand local regulatory frameworks and environmental standards. 15. Develop localized strategies for alternative fuel implementation. Skill Development Objectives 16. Enhance technical decision-making capabilities. 17. Develop a holistic understanding of alternative fuel system design and implementation. 18. Foster a culture of innovation and sustainability in cement production. Unique Value Propositions ● Egypt-focused perspective ● Comprehensive technical and strategic approach ● Emphasis on quality, safety, and sustainability ● Practical, implementation-oriented training Recommended Participants ● Cement plant managers ● Production engineers ● Process engineers ● Quality engineers ● Environmental specialists ● Research and development professionals ● Sustainability managers ● Regulatory compliance officers This structured course outline provides an in-depth approach to alternative fuel systems in cement production, specifically tailored to the Egyptian context. The objectives and content are designed to equip participants with the knowledge, skills, and strategies needed to effectively integrate alternative fuels while maintaining quality, ensuring safety, and promoting sustainable innovation.

Course objectives

At the end of the program, participants will be able to:- By the end of this course, participants will be able to:

- 1. Understand alternative fuel systems and their role in sustainable cement production.

- 2. Identify and evaluate various types of alternative fuels and raw materials suitable for cement production.

- 3. Assess the impact of alternative fuels on clinker chemistry, mineralogy, physical properties, reactivity, grindability, and cement quality.

- 4. Optimize raw mix design to accommodate alternative fuel utilization while maintaining product quality.

- 5. Implement effective process monitoring and control strategies for stable and efficient operation with alternative fuels.

- 6. Comply with environmental regulations and minimize emissions through appropriate control measures.

- 7. Design and implement alternative fuel systems, considering safety, operational efficiency, and economic viability.

- 8. Analyze case studies of successful alternative fuel projects to identify potential challenges and solutions.

- 9. Foster a culture of continuous improvement by adopting best practices and innovative approaches.

- 10. Make informed decisions regarding alternative fuel integration in specific cement plant operations.

Module 1: Introduction to Alternative Fuel Systems

- ● Overview of alternative fuels and raw materials (AFR)

- ● Environmental and economic benefits of AFR utilization

- ● Global trends and regulatory landscape

- ● Challenges and opportunities in AFR implementation

Module 2: Understanding AFR and Their Impact on Cement Production

- ● Types of AFR: characteristics and suitability

- ● Impact of AFR on clinker chemistry, mineralogy, and physical properties

- ● Raw mix design optimization for AFR utilization

- ● Process monitoring and control for stable operation with AFR

Module 3: Combustion Basics and Technical Foundations

- ● Combustion principles and burner technologies

- ● Volatilization processes and injection strategies

- ● Optimization techniques for combustion and process stability

Module 4: Technical Impacts on Kiln Operations

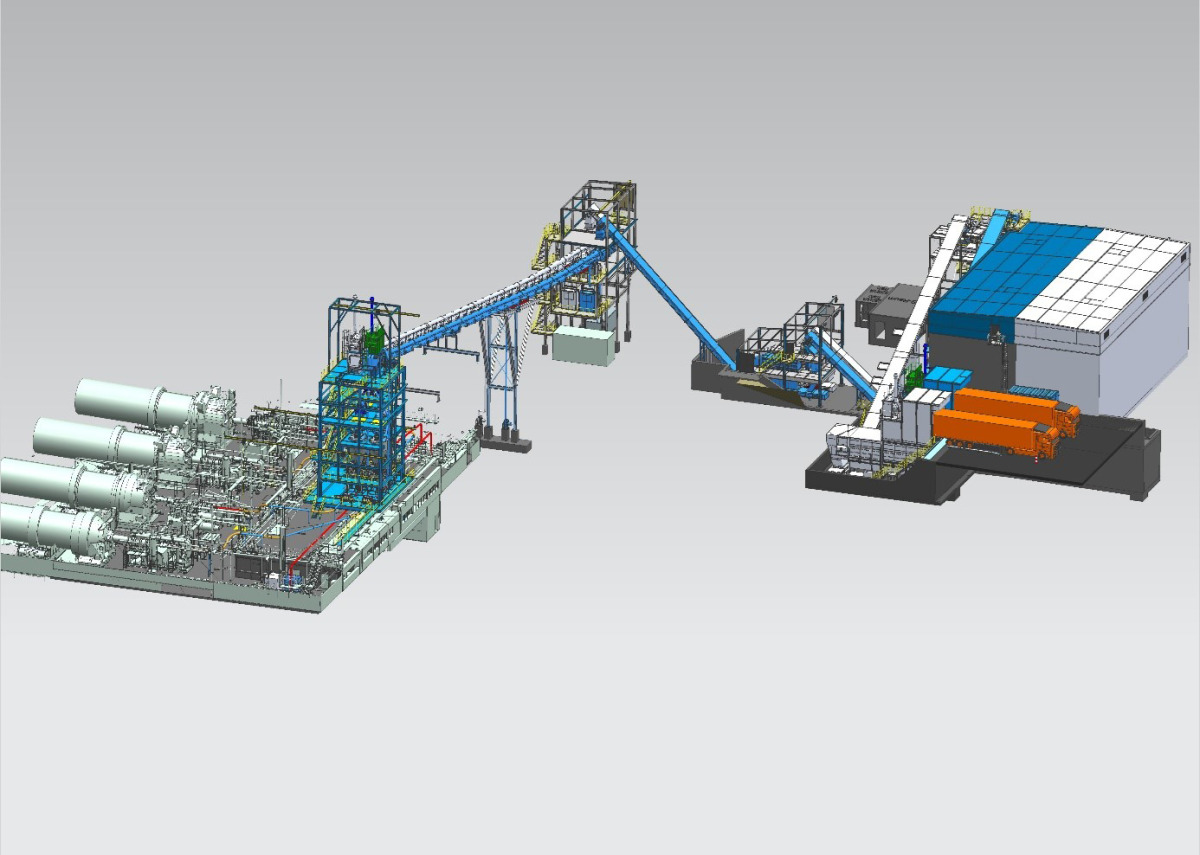

- ● Alternative fuel feeding systems and preparation technologies

- ● Process parameter monitoring and impact on kiln stability

- ● Performance evaluation and emission control strategies

Module 5: Quality Control and Testing Protocols

- ● Quality assessment methods and testing techniques

- ● Impact of AFR on cement properties (setting time, strength, durability)

- ● Continuous quality monitoring strategies

Module 6: Emissions Management and Regulatory Compliance

- ● Environmental standards (Egyptian and international)

- ● Emission monitoring techniques and compliance strategies

- ● Reporting requirements and environmental impact mitigation

Module 7: Safety and Risk Management

- ● Handling protocols for alternative fuels

- ● Risk assessment and safety training requirements

- ● Emergency response planning and hazard mitigation techniques

Module 8: Economic and Sustainability Analysis

- ● Cost-benefit analysis of alternative fuels

- ● Sustainability metrics and long-term economic implications

- ● Strategies for competitive advantage based on alternative fuel use

Module 9: Environmental and Regulatory Considerations

- ● Legislative framework and environmental standards

- ● Emission control measures and monitoring requirements

- ● Strategies for regulatory compliance and environmental impact mitigation